Impacts, Risks, and Opportunities (IRO) for CSRD Reporting

In this article, we’ll break down what IROs are, how to identify and assess them, and what CSRD requires in terms of disclosure.

ESG / CSR

Industries

Every product or service has its own life cycle. From the initial design phase to production and sale, all the way to the moment it's either thrown away or recycled. This is what we call the product's life cycle.

To get a real handle on your company's carbon footprint, you'll want to take a deep dive into LCAs for your various products and services.

Break down what a Life Cycle Analysis is and why it matters

Walk through each stage of the LCA process

Explore the key benefits and common challenges

How Greenly's LCA solution can help your company

A Life Cycle Analysis (also referred to as an environmental life cycle assessment) is an evaluation method used to quantify the environmental impacts of a product or service.

It provides a structured way to assess every stage of a product’s life, helping you spot where environmental impacts occur and how different design choices compare.

The goal? To pinpoint the most efficient and least environmentally detrimental option.

Recognised and standardised at a global level through the International Organization for Standardization (ISO 14040 series), the LCA method provides an all-encompassing approach to assessing environmental impacts. It's about looking at the big picture and understanding how every stage of your product's lifecycle can affect the environment.

Who can benefit from LCA?

International & national agencies

An LCA supports informed policy-making, environmental planning, and long-term sustainable development.

Scientific community

An LCA provides reliable data for research, innovation, and advancing sustainable technologies.

Manufacturers

An LCA offers insights into product design, production processes, and waste management to reduce the product environmental footprint (PEF).

Should your company consider LCA? Absolutely! If your company is looking to:

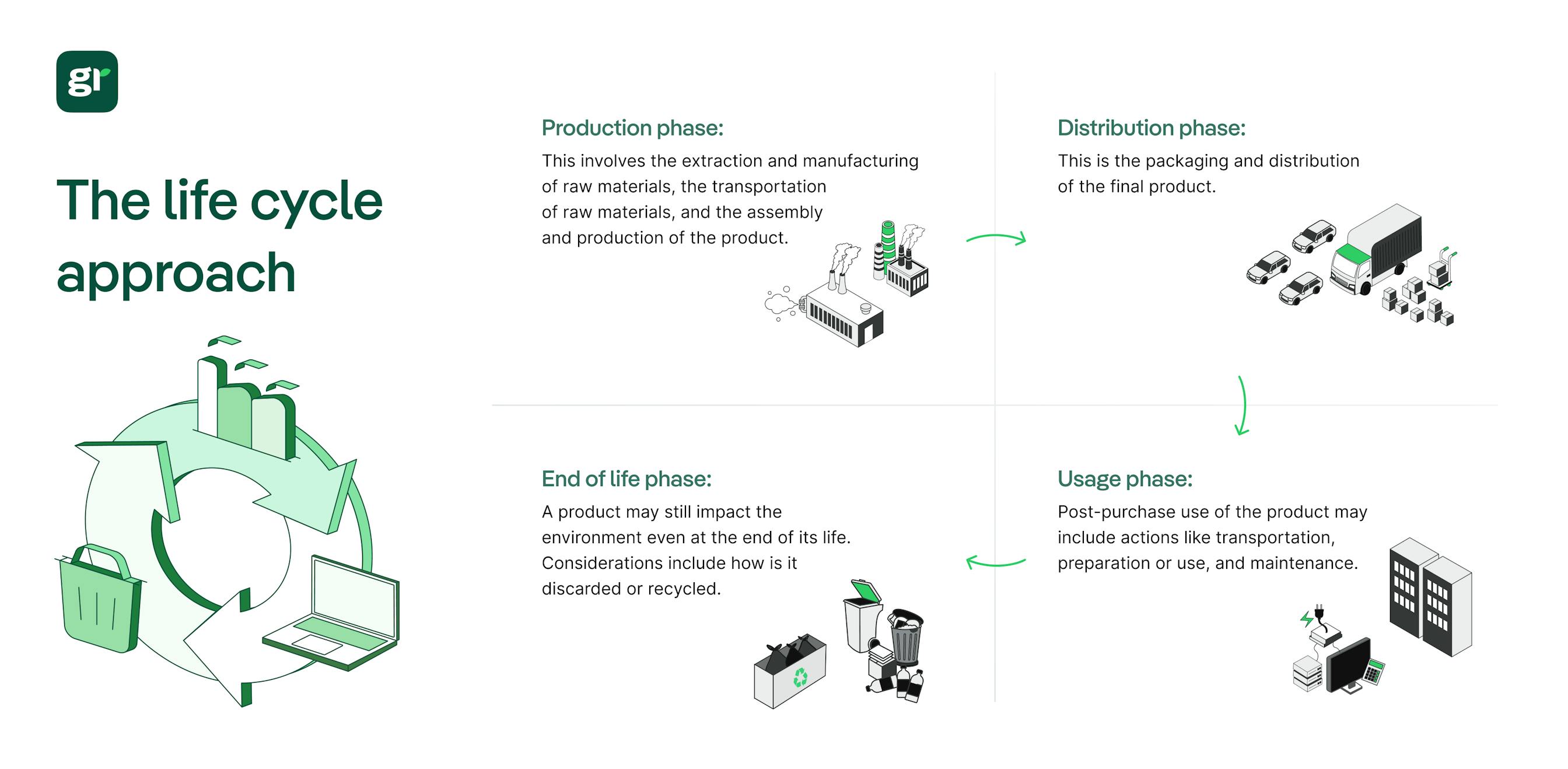

When you apply the LCA approach, you’re essentially creating a full map of everything a product goes through: the materials it uses, the energy it consumes, and the impacts it generates at each stage of its life. This gives you a true “cradle-to-grave” view of how that product affects the environment.

To understand a product’s full footprint, it helps to break its life cycle into three key phases:

| Phase | Key activities | Resource consumption | Environmental impacts |

|---|---|---|---|

|

Creation phase

|

|

|

|

|

Usage phase

|

|

|

|

|

End-of-life phase

|

|

|

|

Looking at these phases side-by-side helps you understand where a product has the biggest impact.

Most of the environmental pressure happens right at the start: manufacturing often demands large amounts of fuel, electricity, water, and sometimes chemicals.

During the usage phase, the footprint continues to grow through everyday activities: powering the product, maintaining it, or transporting it - all of which rely on energy and resources.

What happens at the end-of-life is equally crucial. A product that ends up in a landfill or is incinerated without proper controls can release harmful emissions and pollutants, while recycling or recovery can significantly reduce this burden.

Across all stages, an LCA considers key impact categories such as pollution, biodiversity loss, and CO₂ emissions to build an honest view of a product’s environmental performance.

Life Cycle Analysis (LCA) relies on carefully examining both input and output flows, which track everything that goes into making a product and everything that comes out of it.

Accurate data collection on these flows is at the core of an effective LCA. Each stage of a product’s life cycle, from raw material extraction and manufacturing to transportation and disposal, requires tracking these flows in detail.

By analysing these data points, an LCA can pinpoint the most significant environmental impacts linked to a product or service. This enables us to understand its full environmental footprint and provides a foundation for making informed, sustainable choices about production, materials, or even energy sources.

For example, an LCA might show how much energy is used at each stage of a product’s life. You may find that most of it is consumed during manufacturing, which can highlight opportunities to switch to more energy-efficient processes or materials. Insights like this help companies focus their efforts where they’ll make the biggest difference, cutting emissions and often lowering energy costs at the same time.

LCAs consist of four stages. These are:

The first and most important step in conducting a Life Cycle Analysis (LCA) is to clearly define the goal and scope (ie. what is considered as part of the assessment and what is left out).

First, ask yourself why you're conducting an LCA. Is it to compare different products with the aim of adopting an eco-design approach? Or perhaps it's to help with decision-making in procurement? To improve your environmental impact reporting? Or to provide clearer information to your customers about the environmental footprint of your products?

Whatever your reason, it's important to define your objectives at the outset. You should consider:

Project purpose

Clarify what you're trying to achieve with the LCA - whether it's comparing products, improving design, or supporting internal decision-making.

Functional unit

Define the functional unit used for comparisons - for example, distance travelled per litre of fuel or energy produced per material input.

System boundaries

Outline which stages of the life cycle are included - from raw material extraction to production, use, and end-of-life - and note any data limitations.

Target audience

Identify who the LCA is for - internal teams making strategic decisions or external stakeholders such as customers, partners, or investors.

A note on the functional unit: A functional unit is a unit of measurement that enables final comparisons to be made. It is used to evaluate the service provided by the product throughout its lifecycle. For example, for an LCA comparing different methods of providing heat (like electric heating, gas heating, or a heat pump), the functional unit could be 'the amount of heat provided to keep a house at 21 degrees Celsius for a year'.

When determining the functional unit, it's important to account for:

By carefully defining these factors, you'll be able to create a well-focused LCA that provides meaningful and actionable insights into your product's environmental footprint.

Once you've set your goals and identified what to measure, it's time to compile a Life Cycle Inventory (LCI).

An LCL helps quantify the energy and material inputs, as well as emission outputs across all of the product's life cycle stages - ie. it's a record of all the energy and materials that go into a product and all the emissions that come out at each stage of its life.

The LCI gathers two kinds of data:

This data is usually sourced from a combination of activity-based factors, emission factors, and various databases. When the data isn't available, the inventory can be supplemented with generic (or secondary) data derived from calculations. Putting together this detailed inventory is key to creating a detailed picture of the product's environmental impact across its entire life cycle.

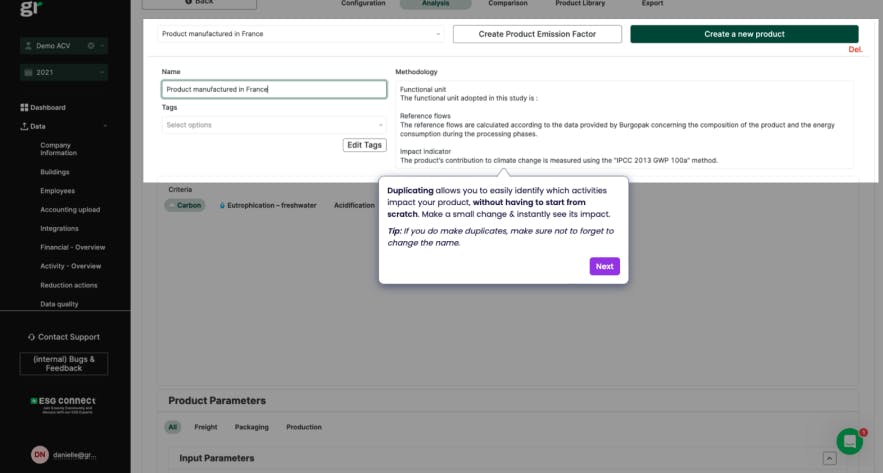

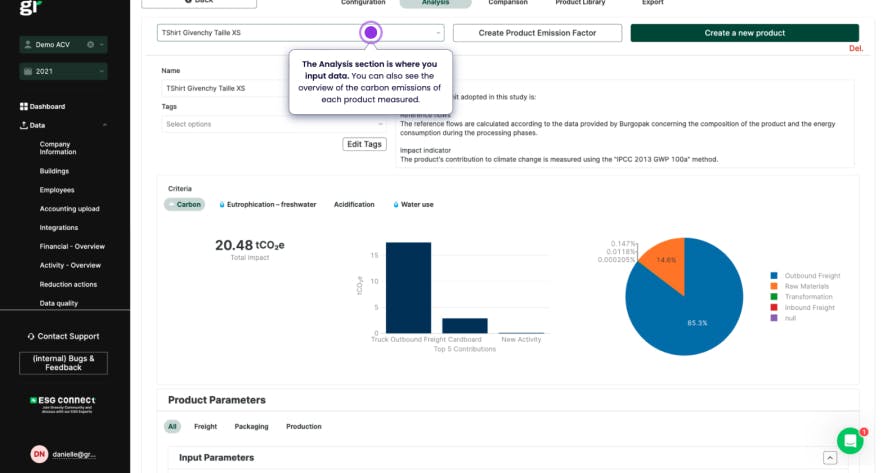

Lots of mistakes can be made at this stage, which is why it is useful to have access to product analysis software or to call in the help of experts like Greenly. This means that control procedures can be put in place to ensure a more reliable life cycle analysis.

At Greenly, we’re experts in conducting Life Cycle Assessments, delivering accurate and dependable analysis. Our experience in managing every stage of the LCA process means we can guide you in avoiding common pitfalls and provide actionable insights for sustainable improvements.

This stage turns the raw life cycle data (ie. the numbers and details about how materials and energy are used) into concrete environmental impact scores.

We assess these impacts based on the materials consumed, energy flows tracked, and the specific calculation methods chosen to characterise each impact.

These flows are typically broken down into two levels of impact: midpoints and endpoints.

In this last stage, we pull everything together to make sense of the full assessment. The goal here is to spot the key areas where the product or process could be made less harmful to the environment and identify changes that could have the biggest impact.

Interpreting these results means taking a close look at where the most significant environmental pressures come from. Is it in the energy used to produce the materials? Or maybe it’s the waste generated at the end of the product's life?

By identifying these “hotspots”, we can figure out where changes are likely to make the biggest difference. This might mean switching to greener materials, reducing emissions during production, or finding ways to cut down on water use.

It's also essential at this stage to double-check the data, making sure everything adds up and there aren’t any big gaps that could skew the results. If any key impacts were missed or underestimated, this is the chance to go back and make adjustments.

Overall, interpreting the LCA results helps businesses make more sustainable choices. Whether it's tweaking a product’s design, selecting more sustainable suppliers, or improving transparency around environmental impact, this stage helps companies to make real, meaningful improvements that align with sustainability goals.

Remember, this entire process is iterative, meaning it needs regular checks and validations to ensure you're on track toward your goals. You might need to to adjust your plan, as some data might not be easily available and the scope of study defined at the outset might need to be tweaked.

Of course, running a Life Cycle Analysis (LCA) isn’t always straightforward, there are a few key challenges and limitations to be aware of:

| Challenge | Description |

|---|---|

|

Data availability & quality

|

Accurate and comprehensive data is essential, but often difficult to obtain — especially across every stage of a product’s life cycle. |

|

Complexity of analysis

|

LCAs require expertise across impact categories, modelling methods, and data interpretation, making the process technically demanding for many organisations. |

|

Cost

|

Collecting high-quality data, analysing it properly, and ensuring accuracy often requires significant financial investment, time, and internal resources. |

|

Time-consuming process

|

A full LCA can take weeks or months due to the depth of data collection and the detailed analysis needed to produce reliable results. |

|

Resource intensity

|

LCAs can demand significant human and technical resources — a challenge for companies without in-house specialists or dedicated sustainability teams. |

Because of these challenges, many companies choose to work with third-party experts like Greenly or use dedicated software to make the process smoother. This takes the pressure off internal teams and ensures the results are accurate, leaving you free to focus on putting the insights into action.

Life Cycle Assessment (LCA) software is instrumental in conducting thorough environmental assessments of products. These advanced tools calculate and analyse potential environmental impacts across a product's entire life cycle.

By leveraging detailed inventory data, LCA software provides a clear view of a product's environmental footprint, including material usage and energy consumption during production.

| Benefit | Description |

|---|---|

|

Precision and efficiency

|

Automates complex calculations and data processing, making assessments faster and more accurate. |

|

Data accessibility

|

Provides access to extensive databases that are tailored to specific industries, materials, or product categories. |

|

Compliance and risk management

|

Helps companies meet environmental regulations and identify areas of risk or improvement ahead of time. |

Alternatively, businesses can conduct an LCA manually with proper data access and understanding. However, it should be noted that manual methods require more effort and can be complex and time-consuming.

Life Cycle Analysis (LCA) becomes even more powerful when integrated with other sustainability tools and frameworks such as carbon footprint calculators, environmental management systems (EMS), and circular economy strategies. This integration allows businesses to adopt a fully comprehensive approach to sustainability.

Combining LCA with carbon footprint calculators provides a detailed measurement of a product's total environmental impact, including supply chain emissions. This helps set more accurate carbon reduction targets. When used alongside an EMS, LCA offers detailed insights that guide continuous environmental performance improvements.

Incorporating LCA into circular economy strategies also helps identify opportunities to minimise waste and optimise resource use throughout a product's lifecycle. This facilitates the design of products that are easier to recycle, reuse, or repurpose, supporting sustainable production and consumption.

In the UK, Life Cycle Analysis (LCA) is gaining popularity due to stringent environmental regulations and the growing emphasis on sustainability from both consumers and businesses.

Several key factors contribute to the rising importance of LCAs in the UK market:

The UK government has committed to net zero by 2050, and various regulations play a key role in driving the adoption of LCAs by businesses:

Extended Producer Responsibility (EPR)

Under EPR, manufacturers take greater responsibility for the full lifecycle of their products – including disposal and recycling. LCAs help show where impacts occur and are essential for demonstrating compliance.

UK plastics packaging tax

This tax encourages the use of recycled content in packaging. LCAs allow companies to compare materials, assess their environmental impacts, and back up their choices when it comes to compliance.

ESG & reporting

As UK businesses face growing ESG disclosure expectations, LCAs provide robust product-level data that can feed into sustainability reports and help demonstrate credible environmental performance.

LCA adoption in the UK is particularly relevant to industries such as:

Life Cycle Assessment (LCA) has become a go-to approach for anyone looking to understand and reduce the environmental footprint of a product or service.

To keep things consistent globally, the method is defined under the ISO 14040 series. These standards give industries and organisations a solid structure to follow when evaluating impacts across a product’s entire journey.

The ISO 14040 series, established by the International Organization for Standardization, sets the standard for Life Cycle Assessment methodologies. This series includes ISO 14040, which outlines the basic principles and framework, and ISO 14044, which provides the specific requirements and guidelines.

Together, they form a comprehensive standard for conducting LCAs, covering everything from data collection and analysis to reporting and verification.

The purpose of these standards is to ensure consistency, reliability, and transparency across LCA practices globally. By providing a structured approach to evaluating environmental impacts, the ISO 14040 series enables different organisations - regardless of size or location - to assess their products’ impacts in a comparable and consistent way.

This way, companies can make informed, sustainable choices, while customers and stakeholders gain clearer insights into the products they use or invest in.

The ISO 14040 series is widely regarded as the gold standard for environmental impact assessment for several reasons:

Comprehensive coverage

The ISO 14040 series covers every stage of an LCA – from setting goals and scope through to interpreting results – so organisations can track impacts across the whole life cycle of a product.

Consistency & comparability

A standardised method makes it easier to compare different products or services directly – especially useful for multinationals assessing impacts across several countries.

Enhanced credibility

Working to an internationally recognised standard like ISO 14040 strengthens your LCA results and shows a serious commitment to sustainability in the eyes of customers, investors, and regulators.

Transparency & accountability

ISO 14040 requires data, assumptions, and methods to be clearly documented, making it easier for stakeholders to review, question, and trust the findings.

Adaptable across sectors

The ISO 14040 framework works for manufacturing, agriculture, energy, services, and more – which is why it’s become the reference point for LCAs in so many industries.

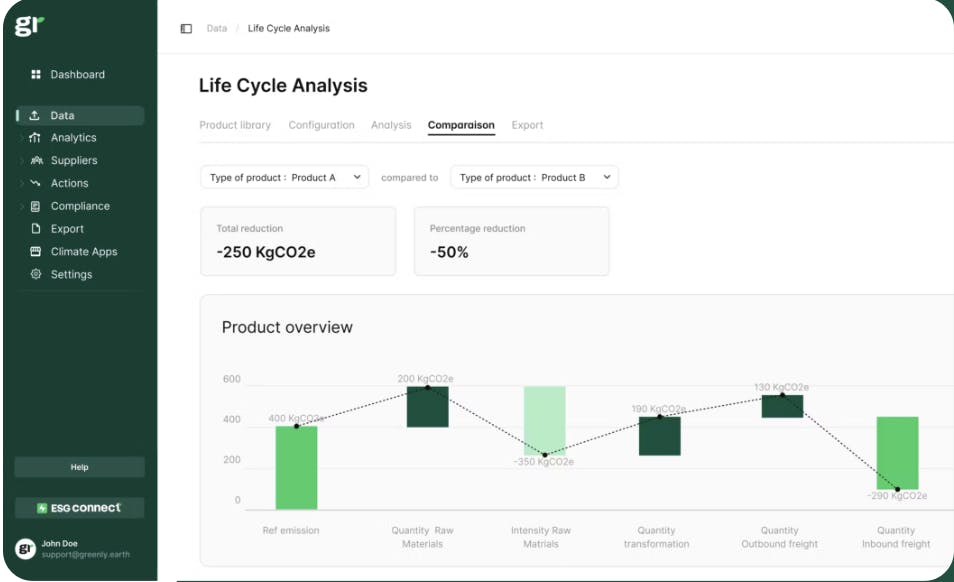

Greenly offers specialised LCA services that extend beyond basic compliance. Greenly's LCA solution empowers businesses to not only assess but also optimise their product's environmental performance.

Greenly tailors LCA to your specific needs, ensuring flexibility and relevance across diverse business scenarios.

Our processes adhere to industry standards like ISO 14040 and 14044, providing baseline impact information across all product phases.

Get in touch with Greenly today to explore our LCA services and start your journey towards a more sustainable future.

Greenly conducted an LCA for CABAÏA, a clothing brand, following industry standards from ADEME and AFNOR. This assessment broke down the environmental impact of each stage in the product’s life cycle, from raw materials to end-of-life. Here’s how the process unfolded step by step:

Data collection: Detailed data is gathered on the composition of each product, down to the gram.

Carbon footprint of materials: Emissions linked to each raw material are calculated using LCA databases and scientific literature.

Carbon conversion: The weight of each material is multiplied by its footprint to estimate total emissions from raw material production.

Fabric manufacturing: Electricity consumption varies depending on spinning, weaving, or knitting processes.

Finishing: Dyeing, printing, and other finishing techniques add to the environmental footprint.

Tailoring: Cutting and sewing emissions depend on the factory location and its energy mix.

Transport modelling: Emissions are calculated across all transportation stages, from raw material delivery to final product distribution, using vehicle-specific emission factors.

Consumer impact: Washing and drying contribute significantly to the product’s overall footprint, depending on the region’s energy mix and consumer habits.

Disposal impact: Emissions vary depending on whether the product is incinerated, landfilled, reused, or recycled. Greenly models each scenario using industry standards.

To find out more about LCA and get advice, read our Energy Vault case study and watch our exclusive video testimonial right here.

Greenly offers a comprehensive suite of services to help your business enhance its sustainability efforts.

Beyond conducting Life Cycle Assessments (LCA), Greenly provides various tools and strategies to promote environmental responsibility and reduce carbon emissions. Here's how we can help your business become more sustainable: