ESG / CSR

Industries

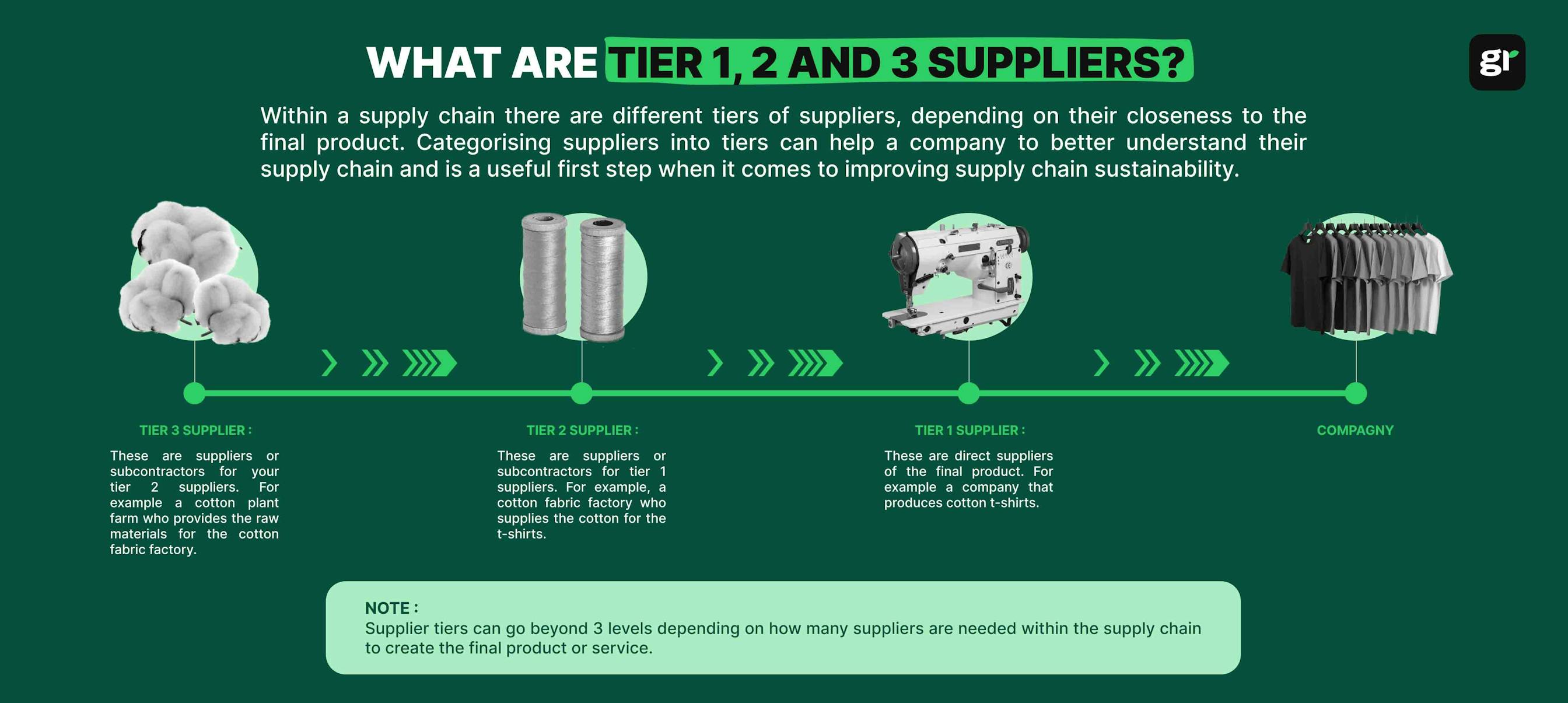

What Are Tier 1, 2 and 3 Suppliers?

All businesses rely on suppliers to create their final product – and that’s where tier suppliers (such as tier 1 suppliers, tier 2 suppliers, and tier 3 suppliers) come into play.

All businesses rely on suppliers to create their final product – and that’s where tier suppliers (such as tier 1 suppliers, tier 2 suppliers, and tier 3 suppliers) come into play.

As companies continue to work towards improving their use of raw materials and develop a sustainable supply chain – tier suppliers are an integral part of supply chain mapping and supplier performance.

It may seem irrelevant to your company where you source your materials. However, as sustainability becomes more important as the baseline for any businesses, it’s important to understand the differences between tier 1, tier 2, and tier 3 suppliers in order to establish transparency and trust across your entire supply chain and within your business.

The truth is, tier 1 suppliers, as well as tier 2 and 3 suppliers, play a part in the amount of emissions a company is responsible for – therefore, it is important to understand them in order to curate greater sustainability in any company.

What are tier suppliers?

Tier Suppliers refer to the method of organising different suppliers into categories in order to delineate which materials are most important in your supply chain. Organising suppliers into these, “tiers” can help stimulate necessary communication between a company and its suppliers.

There are benefits to supply tiering, as it is ultimately a form of supply chain management that can help a business better evaluate supply chain risk management and yield the best outcome possible from their suppliers. As a result, this can improve supply chain resilience and encourage supply chain visibility.

Key components of supplier tiers:

Here are some key components of tier suppliers:

- Suppliers & Data Collection – Effective supply chain management will require accurate and real-time data from tier suppliers, which can then help companies to improve supplier visibility, track essential metrics, ensure regulatory compliance, and improve decision making and procurement processes.

- Tier 1 Suppliers – These refer to the direct suppliers which provide materials, components, or services directly to the company. As a result, tier 1 suppliers usually have a direct contract with the business.

- Tier 2 Suppliers – Tier 2 suppliers are suppliers for Tier 1 suppliers, meaning they provide the raw materials that Tier 1 suppliers use to manufacture finished or semi-finished products.

- Tier 3 and Beyond – These suppliers are further upstream in the supply chain, as they provide various components or specialised services to different supplier tiers – which further diversifies supplier relationships.

- Supply Chain Visibility – Tracking your tier suppliers is essential for supply chain visibility, as it helps to ensure that all manufacturing partners and multiple tiers are helping a company work towards their greater sustainability, ethical sourcing, and compliance goals.

- Risk & Compliance Management – Tier suppliers must be evaluated for financial stability, geopolitical risks, environmental impact, and labor practices to preserve brand image and ensure well-rounded sustainability practices.

- Quality Control & Performance – Tier suppliers should work to meet quality standards and performance metrics, as this is paramount to product integrity and customer satisfaction.

- Sustainability & ESG Initiatives – Suppliers can help companies to align with efforts to go green and reduce their carbon footprint.

- Technology & Data Integration – Many organisations use AI and data analytics to monitor and track their procurement strategies and overall supply chain management.

Remember, supplier tiering started in the automotive industry – but has since expanded to nearly all businesses to depict “how far away” the supplier is from your company and the final product or service your company is trying to produce.

What are the differences between tier 1, 2, and 3 suppliers?

We're going to breakdown the differences between tier 1, tier 2, and tier 3 suppliers – such as by how they contribute to sustainable practices, operational efficiency, their use of physical materials, and their ultimate role in a company's operations.

Here's how each type of tier supplier works in sourcing materials and helping to manufacture a product:

What are tier 1 suppliers?

Tier 1 suppliers are arguably the most important of all the tier suppliers for any business, as tier 1 suppliers are the only suppliers that a business will directly communicate with and have a direct contractual agreement.

This isn’t to say that the other tier suppliers aren’t important – any part of a supply chain is essential to manufacturing any product. However, if there is a tier supplier most essential to the final product – tier 1 suppliers would take the crown.

Importance of tier 1 suppliers for the final product

Tier 1 suppliers are direct suppliers that provide components, materials, or services to a manufacturing company without a middle man. For example, a clothing company that makes t-shirts would consider a factory that produces their clothing as a tier 1 supplier. A company that makes lemonade would call suppliers of ingredients, packaging, and other direct components their tier 1 suppliers. A business that sells annual planners would most likely call a company that manufactures planners their tier 1 supplier.

An important characteristic of tier 1 suppliers is their direct relationship in your supply chain. While they often represent significant costs in your business expenditures, what primarily defines them is their position as immediate suppliers to your manufacturing process

To remember tier 1 suppliers, think of it this way – tier 1 suppliers are one step removed from your end product. If you're making guacamole, the suppliers providing avocados, lime, salt, and other ingredients directly to you are tier 1 suppliers, while companies supplying those farms would be tier 2 suppliers. Tier 1 suppliers are essential because they directly impact the quality, cost savings, and availability of your final product.

What are tier 2 suppliers?

Tier 2 suppliers are most easily defined as the suppliers who provide resources to Tier 1 suppliers.

For instance, if a clothing brand works with a garment manufacturer (tier 1) to produce t-shirts, the fabric mill that supplies the cotton fabric to the garment manufacturer would be a Tier 2 supplier.

Think of a tier 2 supplier as the component essential to the tier 1 supplier's success. Without the tier 2 supplier, the tier 1 supplier could not provide the end product to the company in question – and then, there could never be a final product at all.

What are tier 3 suppliers?

Tier 3 suppliers are the source necessary for the tier 2 supplier to deliver the desired product to the tier 1 supplier.

For instance, continuing with our t-shirt example, if the fabric mill (tier 2) needs raw cotton to create fabric, then the cotton farm that supplies this raw material would be the tier 3 supplier.

A Mexican restaurant serving guacamole has to order their avocados from a produce distributor (tier 1). This distributor has to source their avocados from somewhere – most likely an avocado farm (tier 2). If the avocado farm purchases seedlings or specialised fertilisers from another company, that company would be the tier 3 supplier in the restaurant's supply chain.

A popular almond milk brand would call the factory that manufactures and bottles their almond milk their tier 1 supplier. However, that factory needs almonds to produce the almond milk, so the almond processor (who turns raw almonds into a form usable for almond milk) would be the tier 2 supplier. The almond farm that grows and harvests the raw almonds would be the tier 3 supplier.

Again, following the pattern – think of the tier 3 supplier as providing the essential raw materials or components that the tier 2 supplier needs to create their product.

The table below will compare and contrast the similarities and differences between tier 1, 2, and 3 suppliers:

| Aspect | Tier 1 Suppliers | Tier 2 Suppliers | Tier 3 Suppliers |

|---|---|---|---|

| Definition | Suppliers that directly provide products or components to OEMs (Original Equipment Manufacturers). | Suppliers that provide materials or parts to Tier 1 suppliers. | Suppliers that supply raw materials or base components to Tier 2 suppliers. |

| Proximity to OEM | Closest to OEMs, directly working with them. | Intermediate, serving Tier 1 suppliers. | Furthest from OEMs, dealing with raw materials. |

| Complexity of Products | Highly complex, often fully assembled parts or systems. | Moderately complex, individual components or subassemblies. | Low complexity, raw materials or basic components. |

| Examples | Airbag manufacturers, transmission system suppliers. | Plastic molders, circuit board suppliers. | Metal suppliers, chemical companies for coatings. |

| Relationship with OEM | Direct business relationship and collaboration. | Indirect relationship; mainly interacts with Tier 1. | No direct connection to OEMs. |

| Quality Control Requirements | Strict OEM standards and certifications required. | High-quality expectations but fewer direct OEM requirements. | Basic quality control, usually based on raw material standards. |

| Supply Chain Visibility | High visibility, tracked closely by OEMs. | Moderate visibility, monitored by Tier 1. | Low visibility, often overlooked in supply chain mapping. |

Why are tier suppliers important for sustainability?

Tier suppliers are important for sustainability as they can help to address quality issues and work towards continuous improvement – ultimately leading to more rigorous sustainability initiatives.

In order to become a green company, understanding how your suppliers source their materials is essential in order to brand yourself as a sustainable company. Therefore, it’s important to learn the environmental values of all your suppliers in order to ensure that your end product has been manufactured with the environment in mind from start to finish.

Customers are becoming increasingly aware of the importance of sustainability and eco-friendly products, and are interested in how their favorite face washes or sneakers are made. Delineating your tier 1, tier 2, and tier 3 suppliers can help you customers feel confident in your product, mitigate potential risks, and ultimately – spread the word and increase your business revenue.

In addition to creating this transparency with current and potential customers, having your supply chain mapped out can help your company tackle other sustainability issues – such as reducing emissions through determining whether your tier 1, tier 2, or tier 3 suppliers are contributing to scope 1, scope 2, or scope 3 emissions in your company.

What are the benefits of supply tiering?

Some other benefits of supplier tiering include increased efficiency, improved product quality, and best of all – improved environmental sustainability.

It's true that while supplier tiering started as a way to help a car manufacturer to breakdown their environmental impact whilst undergoing the process of manufacturing a car – the ideals depicted by tier suppliers can now extend to and benefit companies across a wide variety of industries.

Here's a breakdown of the benefits of supply tiering:

- Improve Business Efficiency – Supplier tiering can help improve your businesses efficiency, as a good relationship with your suppliers can help reduce the time between delivery of the product and mitigate back orders or delays.

- Better Quality Products & Attract New Customers – Tier 1 suppliers will have strong intrinsic motivation to increase both their output and quality, as they will have a company completely dependent on them for business of any kind. As the tier 1 supplier ups their quality and production rate, your business will directly benefit from increased sales and new customers.

- Boost Brand Reputation & Reduce Environmental Impact – The most rewarding part of supply tiering is the positive environmental impact it can have, and how it will not only help in the fight against climate change – but improve your business standing, as well.

- Weed Out Inefficient Suppliers – Creating a more sustainable supply chain will ultimately help your business discover which suppliers share the same environmental or social goals that your company does, and ending relationships with the suppliers who don’t can help propel your company towards greater sustainability and transparency – all which will garner the interest of future employees, investors, and customers alike.

Supply tiering is a fundamental element to any business, so choosing the right suppliers that seek sustainability can be essential to the future success of your company.

How to Choose a Sustainable Supplier

Choosing a sustainable supplier will require your company to define its individual goals and communicate them to the relative teams within your organisation.

However, this begs the question – how can you weed out the suppliers that are sustainable from the ones that aren’t?

Here's how your company can figure out the sustainable suppliers from the not-so sustainable suppliers:

Define your sustainability goals

First, it’s important to clearly define your own company’s sustainability goals, and then illustrate these to your procurement team – the team in your company that discovers and acquires various goods and services. Your procurement team can decide if the current tier supplier is aligned with your company’s other environmental goals, or if they aren’t and if it’s time to look elsewhere for a new supplier.

This isn’t too difficult of a task, as many suppliers these days, just like companies, are being asked to address their environmental impact to the public in order to establish transparency. Suppliers want to avoid greenwashing as well, because then companies won’t trust them to provide businesses with the materials they need.

Implement a method to track progress

However, it is still important that your procurement team implements a method to track the progress of both the company’s sustainability goals, as well as the supplier’s – to ensure everyone’s end of the bargain is being met and to maintain a trustworthy partnership.

Therefore, it isn’t illogical for your procurement team to ask the tier 1, tier 2, or tier 3 supplier for their sustainability objectives – as that data will be the only surefire way to ensure that your company is partnered with a sustainable supplier. Or at least, a supplier that is putting their best foot forward to be sustainable. As long as the supplier has sustainability targets in mind and is implementing the concrete actions necessary to achieve them, they are doing their fair share and the supplier can be considered sustainable – unless those goals are not met later.

Review and verify a supplier's previous sustainability efforts

However, that isn’t to say that long-term sustainability and data regarding those sustainability goals isn’t important. An important part to choosing a sustainable supplier is to check their track record: have they followed through with their previous sustainability goals? This is vital, because if the supplier hasn’t demonstrated success in sustainability before – it isn’t guaranteed that they will be dedicated towards success in sustainability in the future.

If this is too daunting a task, to measure and track the previous and future data of a supplier’s sustainability goals – a safe bet is to seek suppliers that have acquired certifications proving their green efforts.

Examples of these certifications include:

Moving forward, requiring that future suppliers have or are seeking to hold one of these certifications may be the most surefire way to ensure sustainability amongst your supply chain.

Monitor for continuous supply chain sustainable efforts

Finally, it’s important to monitor the sustainable efforts of all three supply tiers: including tier 2 and tier 3 suppliers. As explained before, customers are becoming more interested in how their favorite face wash ended up in the bottle they bought – as opposed to simply picking out a bottle with aesthetic packaging they like.

This is why it's important to clearly illustrate to your customers the entire manufacturing process, which means the sustainability efforts from your tier 2 and tier 3 suppliers are just as important as your tier 1 suppliers.

At the end of the day, sustainability is important to everyone involved in the manufacturing of a product these days – as suppliers won’t have business, and businesses won’t have customers if they can’t ensure their efforts to be sustainable.

Everything has to be built from the ground up, and given materials provided by suppliers is where it all starts – it’s important to understand how tier 1, tier 2, and tier 3 suppliers source their materials, so that you can be sure you provide both an eco-friendly and trustworthy product to your customers.

What about Greenly?

If reading this article on four tips to become a green company has made you interested in reducing your carbon emissions to further fight against climate change – Greenly can help you!

Greenly can help you make an environmental change for the better, starting with a carbon footprint assessment to know how much carbon emissions your company and your supplier produce.

Click here to learn more about Greenly and how we can help you reduce your carbon footprint.

Don't wait any longer, take the first step towards reducing your carbon footprint by requesting a free and non-binding demo with one of our experts today and finding the solution that best fits your business needs.