Impacts, Risks, and Opportunities (IRO) for CSRD Reporting

In this article, we’ll break down what IROs are, how to identify and assess them, and what CSRD requires in terms of disclosure.

ESG / CSR

Industries

Chemicals are everywhere – from the cleaning products under your sink to the materials used to manufacture your favourite gadgets. But have you ever stopped to think about the risks these substances might pose to human health or the environment? For years, these concerns went unaddressed on a broad scale, leaving significant gaps in regulation. That’s where the EU’s REACH Regulation comes in.

REACH, which stands for Registration, Evaluation, Authorisation, and Restriction of Chemicals, is one of the most comprehensive chemical safety regulations in the world. Since its introduction in 2007, it has been pivotal in ensuring that chemicals are used safely, all while building innovation and sustainability across industries.

👉 In this article, we’ll explore everything you need to know about REACH – from its key objectives and processes to its impact on businesses and the environment.

The REACH Regulation, short for Registration, Evaluation, Authorisation, and Restriction of Chemicals, is the cornerstone of the European Union’s approach to managing the risks posed by chemical substances. Effective since June 1, 2007, REACH was designed to protect human health and the environment while simultaneously promoting innovation and competitiveness within the EU chemicals industry.

At its core, REACH shifts the responsibility for chemical safety onto the companies that manufacture, import, and use these substances. This means businesses must proactively gather data on the properties and potential hazards of the chemicals they work with and submit this information to the European Chemicals Agency (ECHA) for assessment.

But REACH doesn’t stop there. It goes beyond merely identifying risks – it requires companies to implement measures to manage these risks effectively. The regulation also encourages the phase-out of hazardous substances by promoting the development and use of safer alternatives.

One of REACH’s most significant achievements is the creation of a centralised database managed by ECHA. This database not only helps regulators assess chemical risks but also provides consumers and professionals with access to hazard information, ensuring transparency across the board.

Key takeaways:

👉 REACH is more than just a set of rules – it’s a proactive approach to safeguarding our future while driving sustainable progress across industries.

Before REACH, chemical regulations across Europe were fragmented and often inadequate. Many substances were in widespread use without proper evaluation of their risks to human health and the environment. Action was typically reactive – problems were addressed only after evidence of harm emerged, often too late to prevent damage.

REACH was introduced to change this. It aimed to take a proactive approach, ensuring that the risks of chemicals are identified and managed before they can cause harm. By requiring companies to collect data on the safety of their substances and submit it for review, REACH set a new standard: no data, no market.

Beyond safety, REACH also sought to encourage innovation. By pushing companies to phase out hazardous substances in favour of safer alternatives, the regulation became a driver for research and development in green chemistry. This focus on sustainability not only helps protect people and the environment but also strengthens the EU’s position as a leader in the global chemicals industry.

REACH’s stringent evaluation and restriction processes have led to the banning of numerous chemicals that pose significant risks to human health and the environment. These bans highlight REACH’s proactive approach to reducing exposure to hazardous substances and encouraging safer alternatives. Below are some examples of substances that have been restricted or banned under REACH, along with the reasons behind these decisions.

| Substance | Reason for Ban | Impact of the Ban |

|---|---|---|

| Chromium VI compounds | Highly toxic and carcinogenic, posing risks to workers and causing soil and water contamination. | Driven innovation in safer alternatives for metal finishing, significantly reducing occupational exposure and environmental contamination. |

| Asbestos | Linked to severe health impacts such as lung cancer, asbestosis, and mesothelioma. Previously widely used in construction and insulation. | Phased out asbestos-containing materials, protecting workers and the public from long-term health risks. |

| Lead in paints | Highly toxic, particularly to children, causing neurological damage and developmental delays. | Reduced public health risks and encouraged the development of safer, lead-free alternatives. |

| Phthalates (e.g., DEHP, DBP) | Used as plasticisers but linked to reproductive toxicity and hormonal disruptions. | Encouraged the use of non-toxic plasticisers in consumer products, ensuring safer toys, packaging, and other items. |

| PFAS (per- and polyfluoroalkyl substances) | Persistent 'forever chemicals' that bioaccumulate and are linked to cancer and immune system suppression. | Phasing out PFAS promotes eco-friendly alternatives and improved waste management practices. |

The REACH Regulation and its related frameworks are continuously evolving to address emerging concerns and improve chemical safety. The most recent update is the revised Classification, Labelling, and Packaging (CLP) regulation, which came into force on 10 December 2024. These updates are designed to enhance the identification, classification, and communication of chemical hazards, ensuring that businesses and consumers have access to clear, accurate information.

Key changes under the revised CLP regulation:

💡 Companies are encouraged to review their portfolios and update classifications as needed. Proactive compliance not only ensures adherence to the new rules but also demonstrates a commitment to safety and sustainability in an increasingly regulated market.

The EU’s REACH Regulation is often considered one of the most comprehensive and stringent chemical safety frameworks in the world. It sets a high standard for identifying, managing, and restricting hazardous substances, but how does it compare to regulations in other regions, such as the United States?

One key distinction is that REACH operates on a “precautionary principle”. This means that substances must be proven safe before they can be marketed or used in the EU. In contrast, regulations in countries like the US often take a more reactive approach, requiring evidence of harm before action is taken to restrict or ban a chemical. For example:

REACH applies to nearly all chemical substances, including those in everyday products like electronics, furniture, and cosmetics. This broad applicability contrasts with the US Toxic Substances Control Act (TSCA), which focuses more narrowly on industrial chemicals, leaving some consumer goods less regulated.

REACH places significant emphasis on phasing out Substances of Very High Concern (SVHCs) and encourages companies to adopt safer alternatives. In the US, while there is growing attention on safer substitutes, this is not yet a regulatory requirement on the same scale as REACH.

The EU’s “right to know” provisions under REACH (eg. Article 33) allow consumers to request information on whether a product contains SVHCs. Such consumer rights are not as prominently featured in other chemical safety regulations.

The EU’s leadership in chemical safety often sets a benchmark for other countries. However, these differences also create challenges for companies operating globally. A substance restricted under REACH may still be allowed in other regions, leading to discrepancies in product formulations and compliance strategies. For example, cosmetics containing certain parabens or PFAS may still be marketed in the US, despite bans in the EU.

REACH is built around four core processes – registration, evaluation, authorisation, and restriction. Together, these form a comprehensive framework to ensure the safe use of chemicals throughout their lifecycle. Here’s how each component works:

At the heart of REACH is the principle of “no data, no market”. Any company manufacturing or importing chemical substances into the EU in quantities of one tonne or more per year must register these substances with the European Chemicals Agency (ECHA). This involves providing detailed information about the substance’s properties, potential hazards, and safe use.

The registration process requires collaboration between companies working with the same substances to reduce duplication and costs. For many businesses, this stage is resource-intensive but critical – without a valid registration, the substance cannot be legally marketed in the EU.

Once substances are registered, ECHA and the member states assess the information submitted. This evaluation phase has two main goals:

If concerns arise, ECHA can request additional testing or restrict a substance’s use.

Some chemicals, known as Substances of Very High Concern (SVHCs), pose significant risks. These include carcinogens, substances toxic to reproduction, and those that persist in the environment. Such substances are added to a list requiring authorisation for specific uses.

The authorisation process pushes companies to seek safer alternatives. While these substances can still be used in limited cases where no viable substitute exists, businesses must prove their use is justified and that risks are adequately controlled.

For substances that present unacceptable risks, REACH can impose restrictions or outright bans. This ensures that dangerous chemicals are managed effectively or removed from the market entirely, protecting both consumers and the environment.

One of the defining features of REACH is its broad applicability. It doesn’t just affect chemical manufacturers, its reach extends across a wide range of industries and companies. If your business deals with chemicals in any capacity, it’s likely you have obligations under REACH. Here’s a breakdown of who the regulation applies to:

If you produce chemical substances in the EU – whether as raw materials for other industries or for use in your own products – REACH directly applies to you. Manufacturers are responsible for identifying risks associated with their substances and providing safety information through registration with ECHA.

Importing chemicals, mixtures, or even finished goods like furniture or electronics into the EU comes with REACH responsibilities. If the substances in these products exceed the one-tonne annual threshold, it’s your duty as the importer to ensure they are registered and meet REACH requirements.

Many companies use chemicals as part of their production or professional activities without realising they may have obligations under REACH. For example:

While downstream users don’t need to register substances themselves, they must ensure the chemicals they use are sourced from REACH-compliant suppliers and that they follow safety guidelines provided in the registration dossiers.

If you’re based outside the EU and exporting products to the EU, you’re not directly bound by REACH. However, compliance becomes your responsibility if you appoint an EU-based “only representative” to handle registrations on your behalf. Otherwise, it’s the importer’s obligation.

The bottom line: REACH’s scope is vast and touches almost every sector – from agriculture and construction to cosmetics and electronics. Even if you’re not directly manufacturing or importing chemicals, as a downstream user, your role in the supply chain could still bring REACH obligations. Ignorance of the regulation isn’t a defence - ensuring compliance is a shared responsibility across industries.

REACH is a regulation with serious implications, and its effectiveness hinges on robust enforcement. Ensuring compliance across the EU is critical to achieving its goals of protecting human health and the environment. This is why REACH has a well-defined enforcement framework to address instances where companies fail to meet their obligations.

Enforcement of REACH falls primarily to the national authorities of each EU member state. These bodies are responsible for monitoring compliance and taking action when violations occur. This may include:

Non-compliance with REACH can result in significant penalties, which vary by country. These can include:

❗️The "no data, no market" principle underpins REACH enforcement. Substances without valid registration cannot legally be manufactured or imported into the EU.

The European Chemicals Agency (ECHA) plays a central role in REACH enforcement by:

To prevent non-compliant products from entering the EU, customs authorities work closely with national enforcement agencies. Importers must provide evidence of REACH compliance for their goods, ensuring that the regulation is upheld even for products sourced outside the EU.

REACH also includes mechanisms for public oversight. Consumers have the right to request information about whether products contain Substances of Very High Concern (SVHCs), holding companies accountable for transparency in their supply chains.

Chemicals can cause significant harm to the environment if not properly managed. Persistent substances, such as PFAS, accumulate in ecosystems, contaminating water supplies and affecting wildlife health. Heavy metals like lead and mercury can disrupt aquatic life, while certain pesticides have been linked to biodiversity loss, including the decline of pollinators like bees. The impact of hazardous chemicals isn’t just local – it can spread across ecosystems, leading to long-term consequences for soil, air, and water quality.

At its core, REACH isn’t just about managing risks – it’s about creating a safer and more sustainable future. By addressing the impact of chemicals on the environment, the regulation plays an important role in protecting ecosystems and promoting long-term sustainability.

One of REACH’s primary objectives is to minimise the release of harmful substances into the environment. Through its evaluation, authorisation, and restriction processes, the regulation ensures that substances with significant risks are either tightly controlled or removed from the market entirely. This reduces pollution in air, water, and soil, safeguarding natural habitats and biodiversity.

REACH pushes industries to innovate by encouraging the replacement of hazardous substances with safer alternatives. Substances of Very High Concern (SVHCs), for example, are subject to strict authorisation requirements, motivating companies to invest in research and development for sustainable solutions. This shift not only benefits the environment but also drives progress in green chemistry.

The public database maintained by the European Chemicals Agency (ECHA) is a powerful tool for environmental protection. By making information about chemical hazards accessible, REACH empowers businesses, regulators, and consumers to make informed decisions. This transparency creates accountability and helps to build trust in the safety of products used across industries.

REACH complements broader EU sustainability initiatives, including the European Green Deal and the circular economy action plan. By ensuring that chemicals are managed responsibly throughout their lifecycle – from production to disposal – the regulation supports the shift towards a cleaner, more resource-efficient economy.

For many businesses, REACH compliance represents a significant shift in how they handle chemicals. While the regulation has brought undeniable benefits in terms of safety and sustainability, it also comes with its fair share of challenges. From administrative complexity to financial burden, companies often face hurdles when meeting REACH’s requirements.

| Challenge | Description | Solution |

|---|---|---|

| Administrative burden | Companies are required to gather extensive data about the properties, hazards, and uses of their substances. Registration involves detailed technical documentation and collaboration with other registrants for shared substances. | Hire dedicated compliance experts or external consultants to guide the registration process. Invest in internal training programs to upskill teams on REACH requirements. Use digital tools or software to manage documentation and streamline workflows. |

| Financial implications | Compliance costs include testing, registration fees, hiring specialists, and potential updates as regulations evolve. These expenses can be particularly challenging for SMEs with limited budgets. | Develop a clear budget plan that accounts for REACH compliance. SMEs can explore financial support options, such as EU grants or subsidies designed to assist with regulatory compliance. Collaborate with other registrants to share testing costs. |

| Complex supply chains | Businesses reliant on long supply chains often face difficulty ensuring that all substances meet REACH requirements. Inaccurate or incomplete information from suppliers can threaten compliance. | Conduct thorough due diligence by auditing suppliers regularly. Establish clear communication channels and request documented proof of REACH compliance. Implement supply chain management software to monitor compliance across all partners. |

| Substitution pressures | REACH encourages replacing Substances of Very High Concern (SVHCs) with safer alternatives. Identifying substitutes that meet technical and economic needs can require significant R&D investment. | Allocate resources for research and development into safer alternatives. Partner with industry groups or academic institutions to share knowledge. Leverage government incentives or grants for innovation in green chemistry to offset development costs. |

| Navigating evolving regulations | REACH is continually updated with new substances added to restricted or authorisation lists, requiring businesses to adapt and reassess compliance on an ongoing basis. | Subscribe to updates from the European Chemicals Agency (ECHA) to stay informed about regulatory changes. Appoint a dedicated compliance officer or team to monitor updates and implement changes. Use compliance software to track and adjust processes. |

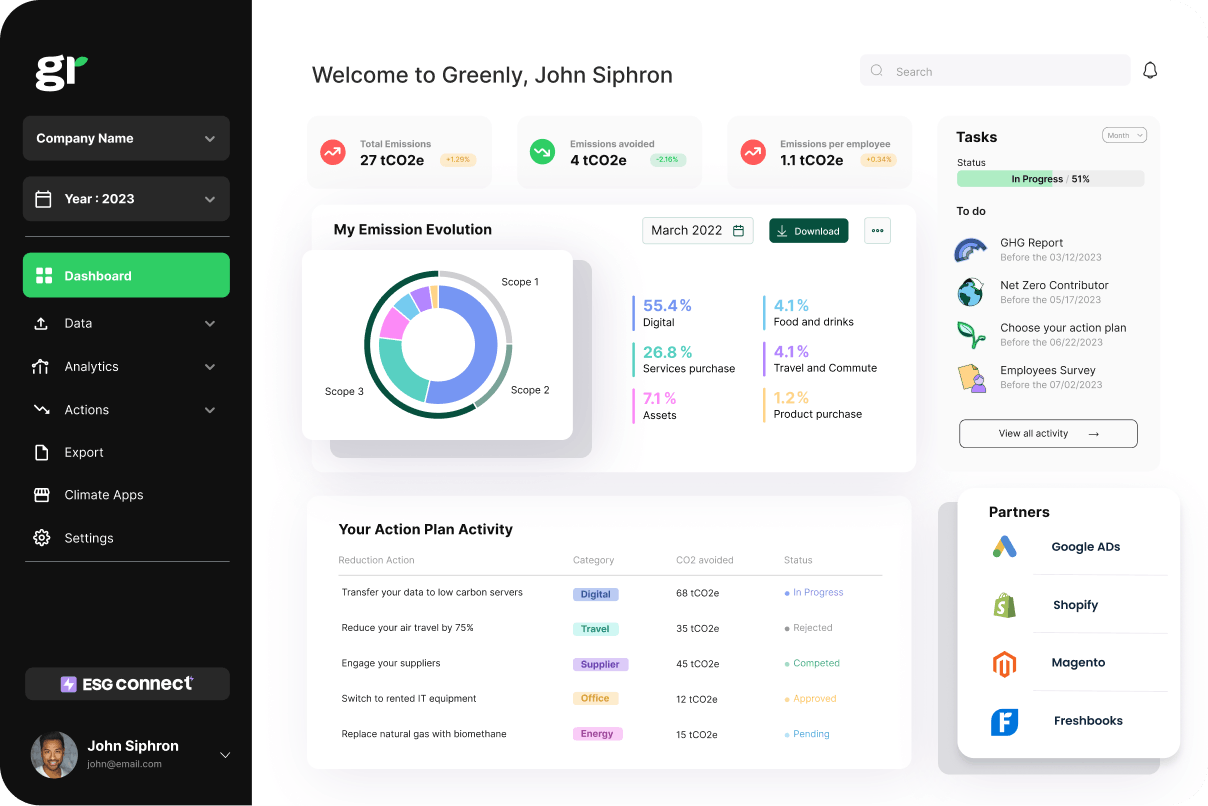

Meeting sustainability goals and managing environmental impact can be challenging, but Greenly is here to help. Our solutions help businesses reduce emissions, improve efficiency, and build more sustainable operations.

Why choose Greenly?

Greenly combines expertise with actionable insights, helping businesses achieve sustainability goals while improving efficiency. By partnering with us, your company can confidently take steps toward a greener future - get in touch with us today to find out more.