What are the 3 Pillars of Corporate Sustainability?

In this article, we'll explore what the 3 pillars of corporate responsibility are, why they're important, and how businesses can turn them into practical action.

ESG / CSR

Industries

Electronics power the modern world, from the smartphones in our hands to the medical devices saving lives. But what happens when these indispensable technologies come at a cost to our health and environment? The European Union’s Restriction of Hazardous Substances (RoHS) Directive offers a solution, tackling the risks posed by hazardous materials in electrical and electronic equipment (EEE). By setting strict limits on substances like lead, mercury, and cadmium, RoHS is driving the global shift toward safer, more sustainable manufacturing.

This directive isn’t just about ticking boxes - it’s a critical tool in reducing electronic waste, protecting ecosystems, and ensuring that the devices we rely on are safe. With its influence expanding far beyond Europe, RoHS has become a benchmark for responsible production.

👉 In this article, we’ll explore the evolution of the RoHS Directive, its goals, and its impact on the electronics industry.

The RoHS Directive was created in response to the growing realization that electronic waste - commonly known as e-waste - was becoming a significant environmental and health hazard. As consumers worldwide embraced rapid technological advancements, the volume of discarded electronics surged, often containing harmful substances like lead and mercury. These toxic materials leached into the environment, posing risks to ecosystems, water supplies, and human health.

In 2003, the European Union took a bold step by introducing Directive 2002/95/EC, commonly referred to as RoHS 1. Its mission was straightforward: to restrict six hazardous substances in electrical and electronic equipment, marking a turning point in sustainable manufacturing. For the first time, companies were held accountable for the materials they used in their products, forcing a reevaluation of supply chains and manufacturing processes.

In 2011, the EU recast the directive as Directive 2011/65/EU, also known as RoHS 2, to address emerging challenges. This update expanded the scope of the directive to include a broader range of products and added new administrative requirements, such as the need for a Declaration of Conformity (DoC) and the affixing of the CE marking on compliant products. RoHS 2 also introduced stricter enforcement measures, signaling a commitment to ensuring compliance across the electronics industry.

RoHS has continued to evolve in response to technological advancements and growing environmental priorities. In recent years, additional hazardous substances have been added to the list of restricted materials, bringing the total to ten. Notably, phthalates such as DEHP and DIBP (commonly used as plasticizers) are now included under the directive.

The EU made further adjustments to RoHS in 2024, reflecting its commitment to balancing environmental goals with practical solutions for manufacturers:

The RoHS Directive applies to a wide range of electrical and electronic equipment. Below is a table summarising the categories and examples of covered products:

| Category | Examples of Covered Products |

|---|---|

| Consumer Electronics | Smartphones, laptops, TVs, gaming consoles, cameras |

| Household Appliances | Refrigerators, washing machines, vacuum cleaners, microwaves |

| Industrial Equipment | Manufacturing machinery, control systems, diagnostic tools |

| Medical Devices | Patient monitors, imaging systems, diagnostic instruments |

| Lighting Products | LED bulbs, fluorescent lamps, other lighting devices |

| Toys and Recreation | Electronic toys, gaming consoles, recreational equipment |

💡 Certain products are exempt, such as military equipment, space-bound technology, and some scientific instruments, where safer alternatives may not yet exist.

The directive limits the use of ten hazardous substances, referred to as the RoHS 10. The table below outlines these substances and examples of the types of products that often contain them:

| Substance | Common Use | Examples of Products |

|---|---|---|

| Lead (Pb) | Soldering, glass in CRT displays, batteries | TVs, older monitors, circuit boards |

| Mercury (Hg) | Fluorescent lamps, switches, batteries | Thermometers, lighting products |

| Cadmium (Cd) | Rechargeable batteries, pigments, coatings | Remote controls, batteries, older LEDs |

| Hexavalent Chromium (Cr6+) | Anti-corrosion coatings, metal finishes | Automotive electronics, industrial equipment |

| Polybrominated Biphenyls (PBB) | Flame retardants in plastics | Housings for electronics like TVs or consoles |

| Polybrominated Diphenyl Ethers (PBDE) | Flame retardants in foam and plastics | Cable insulation, appliance housings |

| Bis(2-Ethylhexyl) Phthalate (DEHP) | Plasticiser in flexible plastics | Cables, vinyl coatings |

| Benzyl Butyl Phthalate (BBP) | Plasticiser for adhesives and vinyls | Vinyl flooring, circuit boards |

| Dibutyl Phthalate (DBP) | Softening agent in plastics and resins | Printed circuit boards, plastic films |

| Diisobutyl Phthalate (DIBP) | Plasticiser for films and coatings | Coated wires, electronic housings |

These substances are restricted to a concentration of 0.1% by weight in homogeneous materials (0.01% for cadmium). The list of restricted substances is under continuous review, with possible additions like TBBPA and MCCPs on the horizon.

Ensuring compliance with the RoHS Directive is essential for manufacturers, importers, and distributors who produce or sell electrical and electronic equipment (EEE) in the EU. Non-compliance can result in hefty fines, market restrictions, or even product recalls. To navigate these challenges, companies must follow a clear set of requirements to demonstrate their adherence to RoHS regulations.

Material Assessment:

Substance Testing:

Supplier Declarations:

Documentation:

Declaration of Conformity (DoC):

CE Marking:

Ongoing Monitoring:

Failure to comply with RoHS requirements can have severe consequences, including:

💡 RoHS compliance is not a one-time effort. It requires continuous monitoring, supply chain collaboration, and adaptation to regulatory updates. Manufacturers who adopt proactive compliance strategies not only avoid penalties but also gain a competitive edge by aligning with sustainability goals and consumer expectations.

The RoHS Directive includes exemptions to allow limited use of restricted substances in specific cases where compliance isn’t yet feasible. These exemptions are carefully reviewed and updated to balance technical challenges with environmental goals.

What Are RoHS Exemptions?

Exemptions permit certain restricted substances when:

Examples include:

Key Updates for 2024

Recycled PVC Exemption:

Cadmium in LEDs:

Proposed Additions:

Expiring Exemptions:

Implications for Manufacturers

The latest updates emphasize the need for manufacturers to:

❗️ These exemptions give industries time to transition, but the pressure to innovate and comply remains strong.

The RoHS Directive has had a significant impact beyond the European Union, inspiring similar regulations worldwide. As a pioneer in restricting hazardous substances, RoHS set a global standard for safer and more sustainable electronic manufacturing, influencing policies in major markets and shaping international trade practices.

Many countries and regions have implemented their own versions of RoHS, often modeled after the EU directive. Key examples include:

| Country/Region | Details |

|---|---|

| China | Introduced in 2006, this regulation mirrors EU RoHS but places additional focus on labeling and packaging requirements for electronic products. |

| Japan | While not directly replicating RoHS, Japan enforces strict substance restrictions through its J-MOSS (Japanese Marking for Presence of Specific Chemical Substances) framework. |

| United States | Several states, including California and New Jersey, have adopted RoHS-like rules, particularly for consumer electronics and hazardous e-waste. |

| India, South Korea, and Turkey | These countries have established their own hazardous substance regulations to align with international trade and environmental standards. |

Impact on International Trade

RoHS compliance has become a prerequisite for companies looking to access global markets. Manufacturers exporting electronics to the EU or countries with RoHS-like regulations must:

Non-compliance can result in restricted market access, costly redesigns, or reputational damage.

The RoHS Directive is highly relevant to companies in the UK and US that manufacture, import, or sell electronic products.

For UK businesses, RoHS compliance remains mandatory under the UK’s version of the directive, which closely mirrors EU regulations post-Brexit.

In the US, while there is no federal RoHS law, several states, including California and New Jersey, have implemented RoHS-like regulations.

Additionally, companies in both countries exporting to the EU must meet RoHS requirements to access its market. Compliance ensures legal access, avoids costly penalties, and aligns with growing consumer and investor demands for sustainable and eco-friendly products.

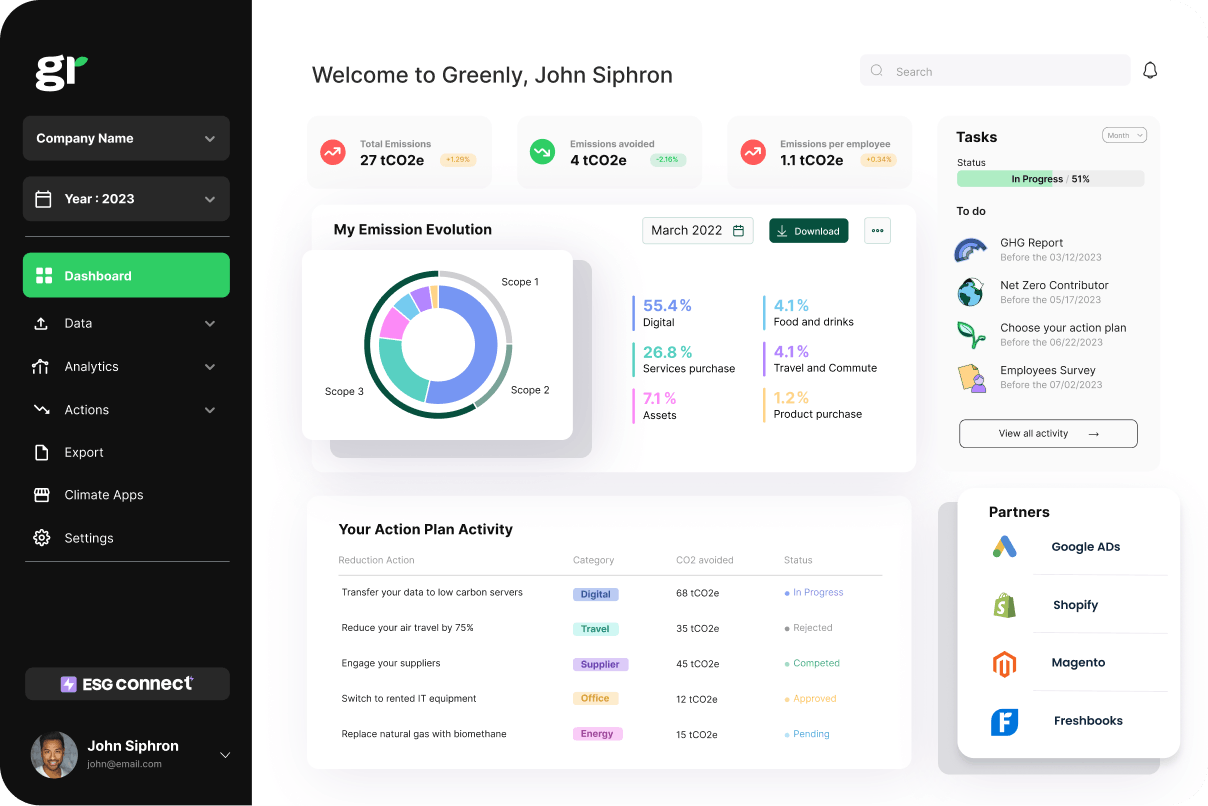

Greenly’s expertise in carbon management makes it easier for companies to navigate the complexities of sustainability while achieving measurable results.

Here’s how Greenly can help your company build a more sustainable operation:

Greenly’s user-friendly platform not only helps you reduce your environmental impact but also positions your company as a leader in sustainability. By improving supply chain transparency and demonstrating a commitment to eco-friendly practices, you can enhance your brand image, attract conscious consumers, and gain investor confidence. Get in touch with us today to start your sustainability journey.