ESG / CSR

Industries

All You Need to Know About Engineered Wood

These days, we’re becoming more concerned with how to build houses in the midst of impending doom from more frequent and severe natural disasters – such as coastal erosion, rising sea level, hurricanes, and more – but can engineered wood really be the solution?

Engineered wood is made from various wood fibers and particles to ensure greater durability and versatility, but is it really the right option during climate change?

In this article, we’ll explain what engineered wood is, the pros and cons, and if it’s the best material to use in the midst of global warming.

What is engineered wood?

Engineered wood, sometimes referred to as composite wood, is a man-made type of wood that is with various particles, veneers, and adhesives which allow for greater strength and versatility in comparison to natural wood.

As it’s used in a wide variety of ways, such as in home construction and commercial buildings, engineered wood is often viewed as more versatile in comparison to natural wood – making it more manipulative than its predecessor.

7 Different Types of Engineered Wood

There are numerous different types of engineered wood, each of which come with their own set of benefits and drawbacks – as these different types of engineered wood may be most suitable for various construction projects.

Here’s a breakdown of the seven different types engineered wood:

- Laminated Veneer Lumber (LVL) – This type of engineered wood is made of multiple wood veneers bonded together with resins, or a solid liquid that can be turned into a polymer. As a whole, LVL is a high-density engineered wood that is most frequently used for framing.

- Laminated Strand Lumber (LSL) – This type of engineered wood is made from small wood strands arranged in a dense, angled pattern – also bonded with resin. As it’s more expensive than traditional wood, its high density and strength make it more durable than Laminated Veneer Lumber (LVL).

- Oriented Strand Board (OSB) – This kind of engineered wood is made by combining wood strands or flakes with adhesives before compressing them. Therefore, OSB is best for load-bearing applications – such as using “fake” wood flooring and roof decking.

- Plywood – As this type of engineered wood is made from thin layers of wood veneer glued together, it’s most suitable for cabinets, flooring, and even boat building.

- Medium-Density Fiberboard (MDF) – This type of engineered wood is made by breaking down hardwood or softwood residuals into wood fibers and mixing them with wax and resin, making it best for non-structural applications such as furniture and cabinetry.

- Particle Board – This type of engineered wood is made from wood chips, sawmill shavings, or sawdust bonded with synthetic resin – making it cheaper and denser than traditional wood. Particle board is most commonly used for furniture and cabinets, but it is prone to moisture issues if not properly sealed.

- Hardboard (High-Density Fiberboard or HDF) – This kind of engineered wood is similar to MDF, but denser – making it a strong and durable engineered wood good for furniture, flooring, and countertops.

Overall, each type of engineered wood offers unique characteristics and properties tailored which can help benefit specific construction projects – as engineered wood can often serve as a viable, more affordable alternative to traditional wood in manufacturing.

What are the pros and cons of engineered wood?

There are several pros and cons to the use of engineered wood, such as how engineered wood can be manipulated to be stronger and more affordable than solid wood – helping to improve stability and resource efficiency.

On the other hand, engineered wood is more prone to damage such as scratches and water stains that traditional wood is more resistant to – adding a potential risk of warping to engineered wood.

The choice to use traditional or engineered wood will ultimately come down to your preference and which properties are most important to you or your business – such as cost effectiveness or moisture resistance.

Here’s a further breakdown of the benefits and drawbacks of using engineered wood:

Pros of Engineered Wood

- More Affordable & Resource – Traditional wood can be extremely expensive, costing a minimum of $600 for lower-end hardwood flooring per 100 square feet. This can make getting your hands on real wood, especially for smaller businesses or first time homeowners, more challenging. Therefore, engineered wood can be a great alternative to real hardwood flooring for those who want to switch out their current carpeting.

- Resistant to Moisture – Engineered wood isn’t as sensitive to moisture or water as traditional wood is, making engineered hardwood flooring a better choice for those who live in areas prone to flooding.

- Less Changes of Warping – As high temperatures across the world continue to wreak havoc on homes everywhere, engineered wood could be a good choice for your home or business if you live in an area prone to extreme heat or temperature changes – as engineered wood is less susceptible to warping than traditional wood.

Cons of Engineered Wood

- Prone to Scratches – Engineered wood, while often manufactured to be more versatile than traditional wood, is also more prone to scratches than traditional wood. This makes engineered wood less aesthetically pleasing than traditional wood.

- Water Stains – In the same vein of how engineered wood is more prone to scratches, is also more vulnerable to visible water stains than traditional wood – which means that engineered wood could be warped more easily, of which cannot be repaired.

- Needs to be Replaced More Often – As engineered wood is more susceptible to scratches and water stains, certain furniture made of engineered wood may need to be replaced more often – such as outdoor or patio furniture. This means that over time, it’s possible that engineered wood could cost you more than purchasing furniture made of traditional wood.

The table below will help break down if engineered wood is the right choice of material for your construction project:

| Factor | Engineered Wood - Pros | Engineered Wood - Cons |

|---|---|---|

| Durability | More resistant to warping, shrinking, and cracking compared to solid wood. | Can be less durable than high-quality hardwood in high-impact environments. |

| Moisture Resistance | Better resistance to moisture and humidity, making it suitable for certain climates. | Still not fully waterproof—prolonged exposure to water can cause swelling or damage. |

| Eco-Friendliness | Uses less solid wood, reducing deforestation and waste. | Some types contain adhesives and chemicals that may emit VOCs (volatile organic compounds). |

| Cost | More affordable than solid hardwood while maintaining a similar look. | High-end engineered wood can be as expensive as some solid woods. |

| Installation | Easier to install; often comes in pre-finished boards. | Cannot always be refinished multiple times like solid wood. |

| Structural Strength | Good for large-scale projects due to its stability. | May not be as strong as traditional solid wood for heavy structural applications. |

| Versatility | Available in various finishes, styles, and sizes. | Some lower-quality options may not match the aesthetic of real wood. |

Ultimately, engineered wood can be more affordable and moisture resistant than traditional wood – but it can also be more prone to water stains and scratches, making the choice between the use of engineered wood and traditional wood contingent on your personal preference and what you are trying to achieve with your specific construction project.

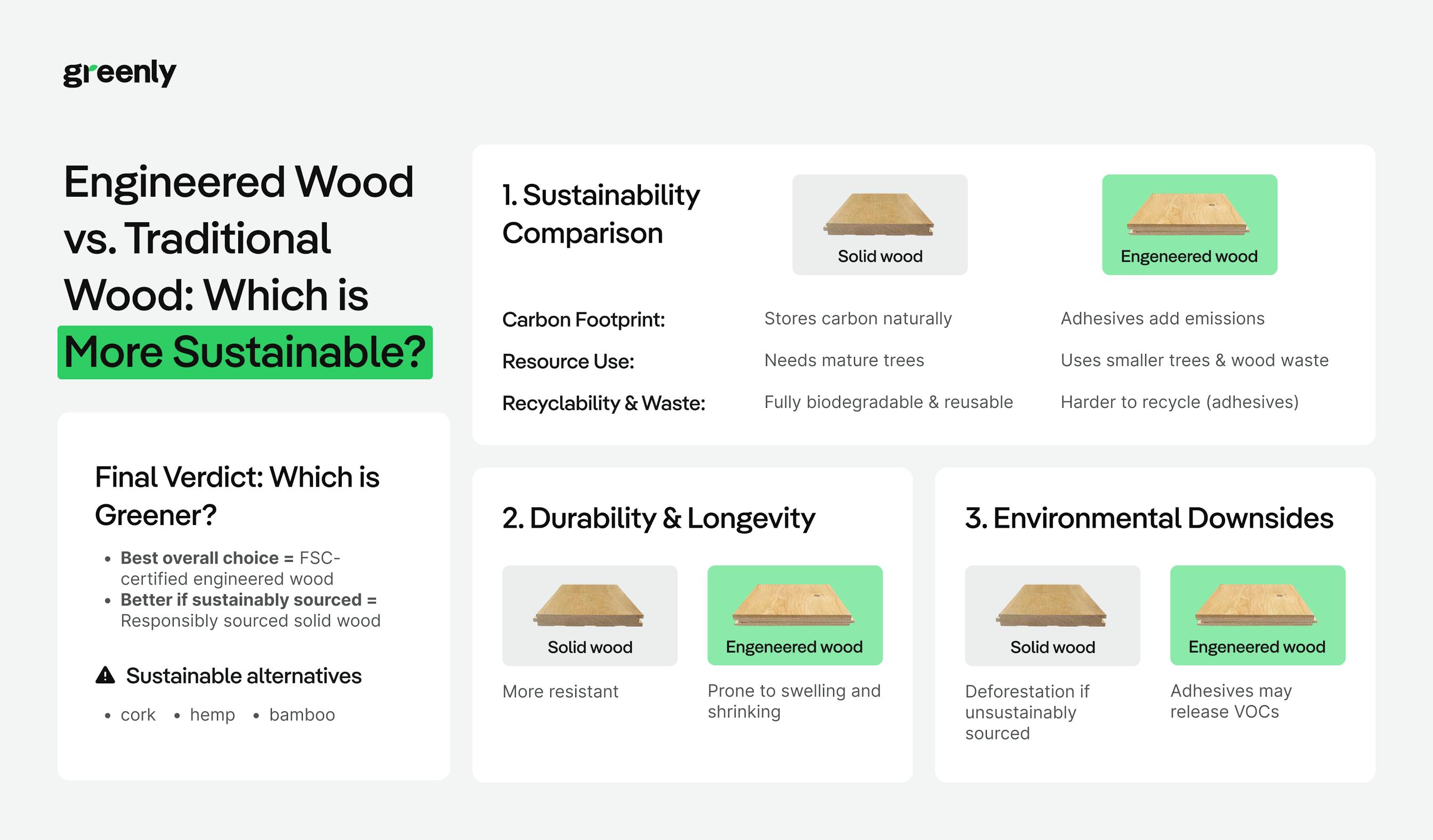

Is engineered wood the most eco-friendly building material?

Since engineered wood is usually made from recycled wood materials, it is eco-friendly in the sense that it helps to promote sustainable wood waste and serve as a renewable alternative to traditional building materials.

Additional reasons why engineered wood can be a good choice for sustainable construction is because it can help to store excess carbon and as a whole, reduce the carbon footprint for the building making use of the engineered wood

Here’s a detailed list of the reasons why engineered wood can be both an eco-friendly choice, and sometimes not the best material to use for the environment:

Reasons Why Engineered Wood Is Good for the Planet (Eco-Friendly Choice)

- Uses Recycled Wood Materials – Engineered wood utilise old wood scraps, smaller trees, and sawdust that otherwise would be used for fireplaces or other commercial purposes, meaning that engineered wood can help to repurpose old materials to become new ones – sort of like upcycling old wood.

- Lower Carbon Footprint – As engineered wood requires less energy to produce than steel or concrete, it can be the best option for construction projects looking to reduce the carbon footprint of their construction project start to finish.

- Renewable Resource – Contrary to steel or concrete, both of which are often used in construction projects – engineered wood is a renewable resource, as it can help with healthy forest regeneration and to to absorb more CO₂ from the atmosphere.

- Reduced Waste – Since engineered wood is less prone to warping the way traditional wood is, it may allow for less waste long-term, as people may not replace engineered wood products as often as those made from traditional wood.

Reasons Why Engineered Wood Is Bad for the Planet (NOT Always an Eco-Friendly Choice)

- Adhesives in Engineered Wood Can Emit VOCs – Some of the adhesives used to bind the various elements that make up the different types of engineered wood may contain formaldehyde, which can emit VOCs (volatile organic compounds) and further impact our indoor air quality.

- Problems with Ethical Sourcing – As ethical sourcing is often the start of recognising a sustainably made product, engineered wood may draw some concerns – as there are still some methods of harvesting wood that contribute to deforestation and habitat destruction.

- Energy-Intensive Manufacturing – Unlike traditional wood, which is harvested and then almost ready to use – engineered wood requires additional production of the various glues and resins necessary to develop the different kinds of engineered wood – sometimes making their carbon footprint higher than their natural counterparts.

- Difficult to Recycle – Unlike solid wood, which is used in a more natural state, many engineered wood products cannot be easily recycled due to their intensive chemical treatments and adhesives – meaning that when no longer usable, they may be discarded and contribute to more landfill waste and GHG emissions.

Overall, engineered wood can be eco-friendly if sourced responsibly and avoids the use of low-VOC adhesives – but it may not be the best choice if it was made with intensive-energy manufacturing, non-renewable adhesives, or unsustainable wood sourcing.

What are some alternatives to engineered wood?

If you still want to make use of sustainable materials for your construction project, but remain wary of the environmental impact of engineered wood – there are several alternatives, such as bamboo, cork, and hempcrete.

Here’s a breakdown of the potential alternatives to engineered wood:

Bamboo

Serving as a fast-growing and renewable source, which is known for its durability and eco-friendly properties – bamboo is a great alternative for several items in your household such as in clothes, sheets, paper utensils, plates, and even your toothbrush!

However, in a similar way to engineered wood – some bamboo products may make use of adhesives with VOCs.

Cork

We may most commonly know cork as the pesky item keeping us from our 5 o’clock glass of wine, but in reality – cork is also a great alternative for many materials used in construction projects.

This is because cork is a 100% renewable resource – as only the bark of cork is used. In addition to this, it serves as an insect repellent and can be used for both flooring and insulation.

The main downside to using cork is that it isn’t as strong as engineered wood or bamboo.

Hempcrete

Hemp isn’t only used for sustainable clothing, but can be used in construction as it can serve as material to help provide insulation within walls. However, similar to cork, hep isn’t a direct replacement for traditional or engineered wood as it’s not best suited for structural uses.

Overall, there are several options for engineered wood, and while it could potentially cause environmental harm, when sourced and produced correctly – engineered wood could help buildings around the world to reduce their environmental impact.

What About Greenly?

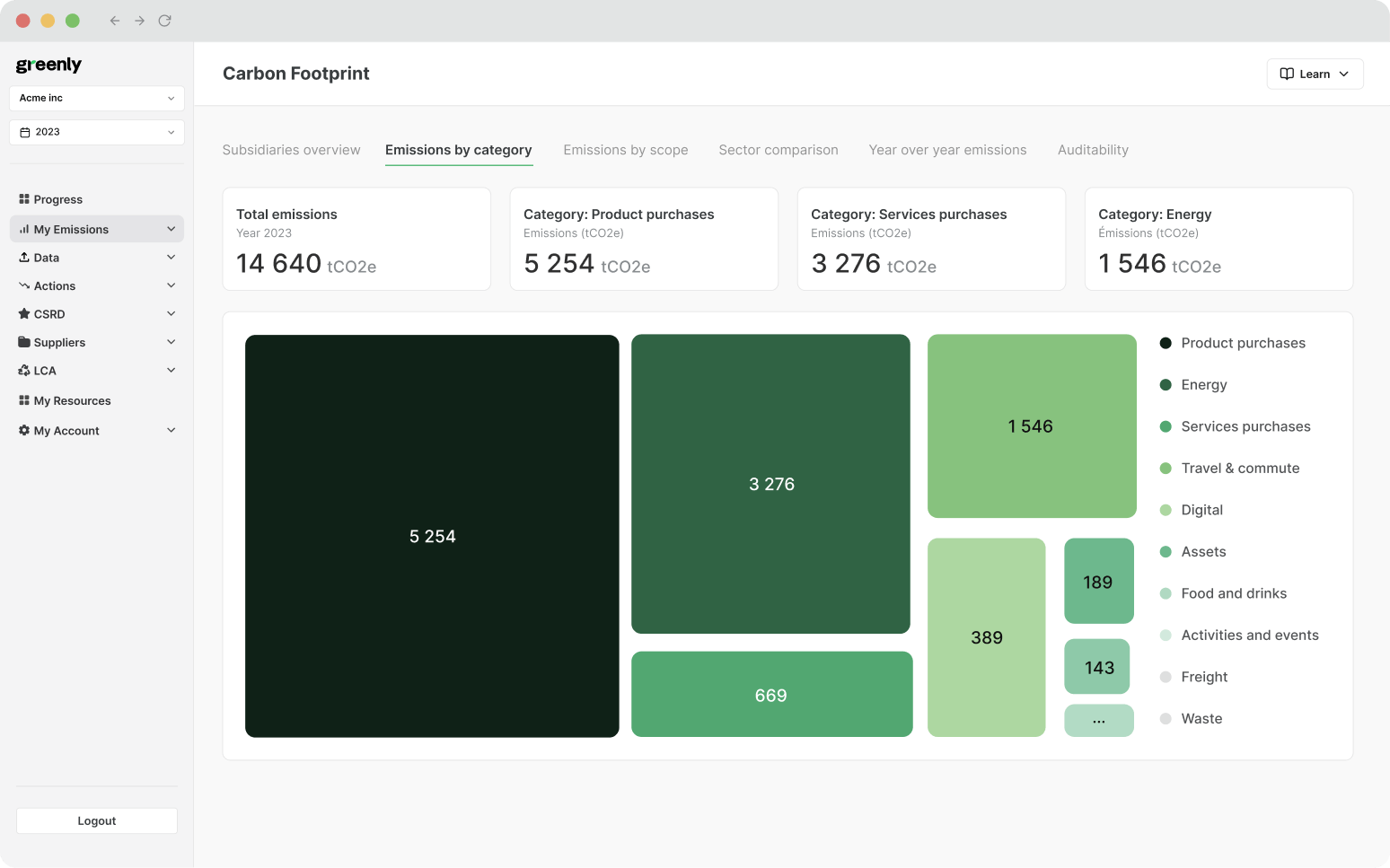

If reading this article about engineered wood has inspired you to consider your company’s own carbon footprint, Greenly can help.

At Greenly we can help you to assess your company’s carbon footprint, and then give you the tools you need to cut down on emissions. We offer a free demo for you to better understand our platform and all that it has to offer – including assistance on how to reduce emissions, optimise energy efficiency, and more to help you get started on your climate journey.

Learn more about Greenly’s carbon management platform here.